Listen to this story

An amputee controls an implanted prosthetic with his own muscles. A military medic 3D prints the bones she needs to treat injuries in the field. Degradable materials guide bone tissue to repair itself—and then disappear into the body as if they were never there.

What sounds like science fiction is underway every day in labs across the University of Tennessee, Knoxville, and UT Institute of Agriculture as researchers from multiple disciplines work on medical solutions that will make life better for patients in the future.

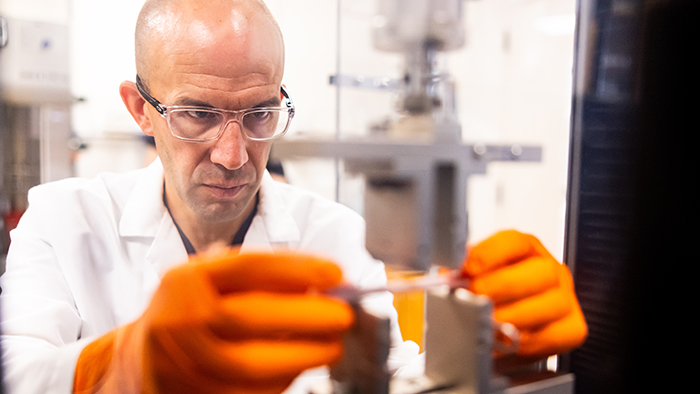

Healing Bones with 3D Scaffolds

At the UT Institute of Agriculture’s College of Veterinary Medicine, biomedical researchers have been testing new technology that allows bones to heal without plates and screws that stay in a patient’s body.

“The traditional approach to repairing a gap in bone is putting implants in the body that help restore form and function, but that process leaves you with this hardware permanently,” says David Anderson, associate dean for research and graduate studies at the college. “We have been developing degradable technologies that heal the body but don’t remain in the body forever.”

A body can lose a certain amount of bone and still heal itself, Anderson explains. Bone grafts represent the current gold standard for those who exceed those limits, but they have their downsides. An autograft—bone tissue taken from elsewhere in a patient’s body—creates a second wound that also needs to heal, while an allograft—bone tissue taken from a cadaver—carries a risk of rejection.

Anderson has been working with Alexandru Biris, director at the University of Arkansas at Little Rock’s Center for Integrative Nanotechnology Sciences, for more than 14 years to develop bone regeneration technology. The highly porous polymeric scaffolds—developed and patented by Biris and refined and validated in collaboration with Anderson—can be used to bridge the gaps in bone but also to guide the existing bone tissue to fill that gap.

“Like the scaffolds you see construction workers using on the side of a building, these scaffolds are mostly space,” Anderson says. “They are 3D structures designed for the bone tissue to grow into the spaces in the scaffold. The scaffold allows the tissue to know where to go.”

Biris’ and Anderson’s goal is for the scaffolds to gain approval from the U.S. Food and Drug Administration for use in people. The two researchers co-founded a start-up company, NuShores BioSciences, to commercialize the technology—which, Anderson says, could change medicine.

“So many of the implants we put in, they don’t need to be there permanently because the bone will heal in a few months,” Anderson says. “This would be a huge advantage.”

Anderson and his fellow researchers also are working to develop technologies for a precision medicine approach to orthopedic injuries. With 3D printing, also known as additive manufacturing, Anderson envisions a future where bones, joints and scaffolds are printed to each patient’s specifications.

“Right now, hospitals have to carry a large inventory of orthopedic devices because one size won’t fit all,” he says. “But with customizable technology, hospital staff could scan and measure the patient and 3D print exactly what they need.”

Anderson imagines new surgical units built with a manufacturing facility at their centers, like the hub of a wheel, with individual operating rooms surrounding it like spokes. Place-based manufacturing would allow the technology to be mobile, which would be helpful for those on military, deep sea or deep space missions, Anderson says.

3D Printing can save time, money

UT Knoxville is already doing this kind of work, thanks to researchers like Rigoberto Advincula, UT-ORNL Governor’s Chair for Advanced and Nanostructured Materials in the Tickle College of Engineering.

“We are using 3D printing to prepare regenerative implants that are degradable—that are harmless for the body to metabolize,” Advincula says. “And this is smart technology, too, because we can 3D print to whatever shape or ratio we desire.”

Instead of taking a solid block of material and milling it to a patient’s specifications, this technology may soon allow technicians to digitally design the needed part from a PET or CT scan and print it directly from an electronic file.

“Traditional methods take longer and are more expensive,” Advincula says. “3D printing should be faster—between a 30 (percent) and 70 percent time savings—and potentially cost less as well.”

Advincula’s lab in UT Knoxville’s Institute for Advanced Materials and Manufacturing goes beyond 3D printing shapes like bones or even scaffolds; it is designing and 3D printing tendons that can attach bone to muscle and testing the movement and mechanical properties of those tendons.

“When we design tendons, they need to have the flexibility of tendons and the durability of bones,” he says.

Implanting prosthetic limbs could restore feeling, function

The 3D-printed tendons in Advincula’s lab complement the work Dustin Crouch is doing on 3D-printed endoprosthetics in his Upper Limb Assist Lab in the Tickle College of Engineering.

“We are testing the concept of a prosthetic limb that can be completely implanted inside the patient’s body,” says Crouch, an associate professor of biomedical engineering. “This will allow some of the remaining muscles in the residual limb to be physically attached to the prosthesis in an anatomically realistic way.”

This concept, known as cineplasty, was tested after World War II with veterans who were amputees, Crouch says. The solutions at that time were clunky and unnatural, like fitting a lever to a muscle to operate an external artificial limb. Between the discomfort of the cable and the limited range of motion, cineplasty was never widely adopted.

Crouch’s goal is to allow patients to move their own limbs by implanting prosthetics attached to muscles with tendons and covered with skin.

“The advantage here is the prosthetic is in the patient’s body,” Crouch says. “Some sensation could be restored with the skin itself—sensations such as pressure and temperature—but the exciting part is that, by attaching prosthetics to the muscles, patients can feel their limbs moving and feel like the device is part of their body.

“Studies show that between 30 (percent) and 40 percent of amputees will get a prosthesis and abandon it because it’s too heavy or uncomfortable,” he adds. “We hope our technology could dramatically improve patients’ lives and allow them to feel like they have their bodies back.”

Ensuring that cells play well with biomaterials

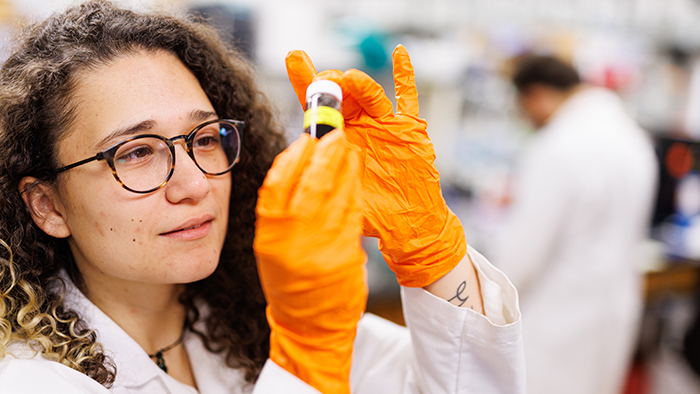

Whether it’s a molded technology like scaffolds or a 3D-printed technology, researchers need to know how cells are going to react to these foreign materials—and that is where Madhu Dhar’s expertise comes in.

Dhar, director of the Tissue Regeneration Laboratory in the College of Veterinary Medicine, uses adult tissue—stem cells derived from adults from discarded tissue, such as the fat discarded during liposuction and gastric procedures—to study cells’ properties and test how they behave when introduced to biomaterials.

“If I can understand the cell, everything will fall into place,” says Dhar, a molecular and cellular biologist who focuses on the use of cell-based therapies for treatment of disease. “We start in a petri dish. What kind of food do the cells like? How do we keep them happy and healthy? If we can keep a cell happy, it does its job in the body.”

Once Dhar and her students study a cell’s properties, it’s time to introduce various biomaterials that can be 3D printed right in the College of Veterinary Medicine. Whether it’s a 3D-printed bone, cartilage or nerve, the material should be compatible with the cell and trigger a healthy and optimal response.

“Our goal is to help heal everything from a simple fracture to a more devastating injury, and these are the tools needed to get us there,” says Dhar, noting that her lab has three bioprinters that can print scaffolds specific to the tissue being studied. “It’s very synergetic, working with materials scientists like Dr. Advincula, biomedical engineers like Dr. Crouch and veterinary surgeons like Dr. Anderson to take our collective research from the bench to the bed for human medicine.”