Listen to this story

With gloves cased in wiring on both hands, Juan Pena made a grasping motion with his right. He demonstrated how the device could make his left hand mimic the movement as it slowly gripped a cup.

A native of Spring Hill, Pena—who received a bachelor’s degree from UT Chattanooga on May 4—spent two years in the UTC mechatronics program working on a project design focusing on a wearable hand rehabilitation system.

In 2022, he joined the mechatronics program after transferring from Columbia (Tennessee) State Community College. He initially planned a career path in medicine out of his desire to help others. When he realized he could contribute to the medical field in other ways—such as designing and building innovative prosthetic limbs and assistive devices—he knew mechatronics was his calling.

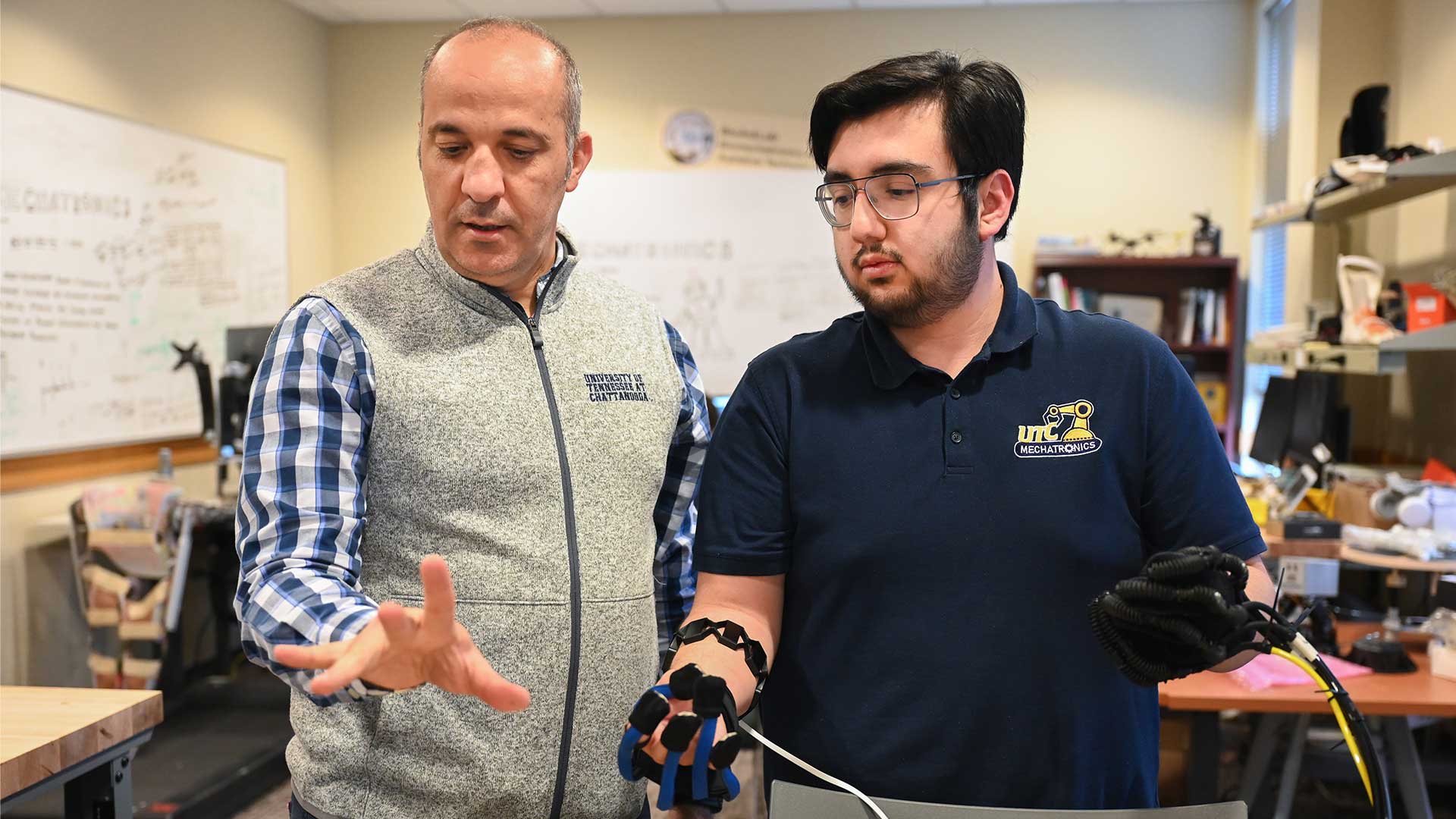

He quickly formed a close relationship with Erkan Kaplanoglu, now director of the Biomechatronic and Assistive Technology Lab, associate professor of mechatronics and interim department head of the UTC Engineering Management and Technology Department.

When Kaplanoglu joined the UTC faculty in 2019, he saw some of the needs in the physical therapy department. He began his work on the hand rehabilitation system with the help of undergraduate researchers, which soon included Pena.

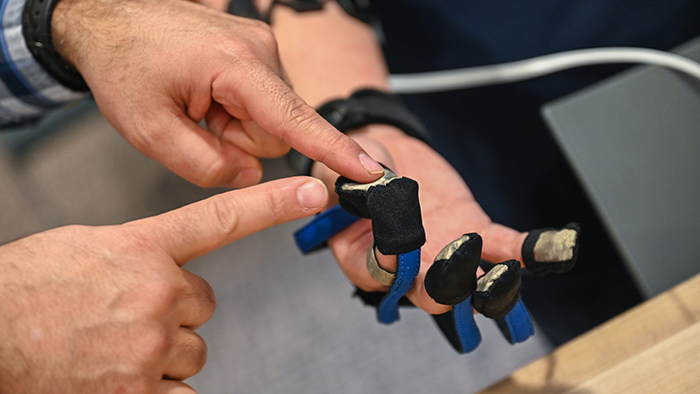

Pena explains how the hand rehabilitation system functions. A sensor glove goes on the nonaffected hand. Strips of sensors attach to each finger, allowing the glove to detect movement. A motor glove then goes on the affected hand and is attached to a pneumatic actuator, which converts the energy of compressed air into mechanical motion allowing the injured hand to mimic motions by the uninjured hand.

“Typically, it is aimed towards people who have suffered from strokes,” Pena says, “and people who have lost motor function in their hands.”

The system also includes a band that can wrap around the hand, which reads electromyography signals showing what muscles are reacting and how much force is being used. The results are displayed on a tablet.

“You can see how much progress you’re making or how much energy you’re putting into the sensor glove,” Pena says.

Though Pena is not the first student to work on the project, his contribution is significant. Much of Pena’s work involved designing the casing that holds the parts that make the system function, including the Raspberry Pi (a small computer), the power source and the actuators.

He says another responsibility was perfecting the once-finicky coding, a largely self-taught skill.

“Looking over the code when I first started, I had no idea what any of it meant,” Pena says. “If I wanted it to work, I had to do it. I watched a lot of YouTube videos, a lot of asking around the department.”

He says time management was one of the most significant learning experiences from the project.

“There are definitely a lot of deadlines,” he says, “but they are soft deadlines. I didn’t have to do it, but I really did. The pressure was there, but it was behind curtains.”

Though it took some time to adapt, Pena says he felt welcome in the mechatronics program from the beginning of his time at UTC.

“I’ve known Dr. K (Kaplanoglu) for a while, and I’ve been very involved,” he says. Working on the robotic hand has “really been an adventure, and I’ve never really taken on a task this monumental.”

Kaplanoglu says not many undergraduate students encounter such an opportunity.

“With the project he has done and the other training he received in the lab, he has trained himself in robotic rehabilitation—a very special subject that has become increasingly important day by day,” he says. “While he was an undergraduate student, Juan gained the knowledge and experience that many people acquire after a long period after graduation.”

With participating in research comes presenting the research—something with which Pena also had to grow comfortable.

He says that one of his greatest accomplishments as a student was presenting at the 15th International MoNE Robot Competition in Turkey in September 2023, where he helped the UTC robotics team win its first international award. The hand rehabilitation system won the Jury Special/Best Design Award over 46 other competitors.

Kaplanoglu says it didn’t take long to convince Pena to travel overseas.

“I asked him, ‘Hey, do you have a passport?’” Kaplanoglu says. “He said, ‘Yes, I have a passport.’ So I said, ‘We’re going to Turkey.”

Pena says it was only his second global excursion. While presenting at an international event was a daunting task, the support from Kaplanoglu made it easier.

“It was scary,” the soft-spoken Pena says. “But I had Dr. K with me. He was the best translator I could ask for.”

As for the future, Pena is excited to see where the hand rehabilitation system goes. He says working alongside Kaplanoglu in the mechatronics lab transformed his college experience.

“It’s definitely taught me different values,” he says. “It’s helped me be more dedicated to what I do, especially with my professors and peers around me.”

“We all work together as a community to make something, because this isn’t something that just one person could do. You’re looking at the work of numerous students and professors working together towards this one goal. I think that’s the awesome part of it.”

Pena says the hand rehabilitation system project inspired him when thinking about a future career in designing rehabilitation technology and medical assistive devices.

“This project has definitely helped me grow both as a person and as a student,” he says. “When I started, I didn’t really know much of anything, but in the last two years, I’ve developed some skills I didn’t know I had in me.”

Kaplanoglu doesn’t describe Pena as his student but as his undergraduate researcher and teammate.

“Juan Pena, dedicated to enhancing the quality of life for patients and individuals with disabilities through the development of assistive systems,” he says, “does not perceive himself solely as a student. He assumes responsibility and approaches his projects with a professional mindset, viewing them as vital preparations for his post-education life and personal growth.”

About UTC Mechatronics

UTC’s undergraduate mechatronics program allows its students to gain hands-on experience with cutting-edge technologies and develop skills in programming and designing electronics and mechanical systems such as automation devices, robots, cars, aircraft, chemical and food-processing machines, appliances, and communication devices. According to Program Director Erkan Kaplanoglu, students also participate in research on “assistive devices, prostheses and rehabilitation robots used in the health care field in the biomechatronics laboratory.”

“The mechatronics program, which began with six students upon its establishment and has now grown to accommodate approximately 100 students within four years, has experienced remarkable expansion since its inception,” he says. “Focused on the domains of automation and robotics, the program offers not only traditional higher education but also extensive hands-on training and industry-supported projects. These initiatives are designed to equip students with practical skills, preparing them effectively for the future.”