By Jennifer Sicking Video by Adam Brimer

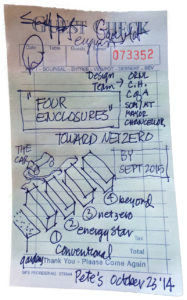

The men sitting around the table at Pete’s Café in downtown Knoxville all posed questions: What can we do together? What can we do with this material? What if. . .?

Then one grabbed a blank receipt and began to sketch an idea, a possibility. Another added an element. A third scribbled a note. They all signed the inked-out plan that Oct. 23 in 2014, and by January 2015, the work began in earnest.

Nine months later, the scrap of paper and the ideas that generated it gave birth to a modified reality with AMIE 1.0, a house and a vehicle produced by a 3-D printer and able to share energy with each other. AMIE, or Additive Manufacturing and Integrated Energy, was born of a collaboration by the University of Tennessee, Oak Ridge National Laboratory (ORNL), and architecture firm Skidmore, Owings and Merrill (SOM), all of which are affiliated with the UT-ORNL Governor’s Chair for Energy and Urbanism, Philip Enquist.

“What’s the secret sauce to doing big things?” asks Roderick Jackson, ORNL building envelope systems research group leader and technical lead for the project, before answering. “It’s bringing together multidisciplinary teams.”

While only 210 square feet, the AMIE house looms large for the future of integrated design and energy.

“Once the intent to elevate the project to moon-shot status and incorporate an entirely additively manufactured building and vehicle with wireless energy transfer was established, we set upon a concept rather quickly,” says James Rose, UT College of Architecture and Design director of the Institute for Smart Structures.

Unlike your computer’s desktop printer, which lays ink on paper to create an image, 3-D printing builds an object layer by layer out of melted plastic or metal. The larger the printer, the larger the object it can print. ORNL has one of the largest 3-D printers in the world.

But the AMIE 1.0 project goes beyond 3-D printing a building—a first—and a vehicle, something Oak Ridge and UT have collaborated on before, from carbon fiber-reinforced ABS (acrylonitrile butadiene styrene) plastic. It integrates energy transfer wirelessly between the building and the car. Cars filling up their batteries from a house’s power source may not be new, but with AMIE, the car can light up the house with power. And it does it all off of the electric grid.

Solar panels power the house, which then can charge the printed utility vehicle, or PUV, which also runs on natural gas. On a cloudy day when the solar rays don’t provide enough energy to fill the house’s battery system, the PUV and its natural gas-powered generator send energy to the house.

Why would you 3-D print a building? What can you do with 3-D printing that’s different from traditional manufacturing?

Asking questions led to innovation. Innovation with an unknown building material. Innovation with energy.

“What we were doing was something that was disruptive to possibilities,” Jackson says. “This was not incremental change to how we build buildings or vehicles.”

This project would change how cars and houses could work together, how cars and houses could be built, how cars and houses could trade energy. It changed what could be possible.

In the spring 2015 semester, Rose led UT Knoxville architecture graduate students in the Governor’s Chair studio to ask questions and envision their own concepts. They researched innovative sustainability practices. They asked how micro-houses work. They asked how to fabricate a building created layer by layer out of plastic. And they engaged in those questions with Governor’s Chair Enquist and select designers from SOM, one of the world’s leading urban planning, architecture and engineering firms, which had completed AMIE’s design, as they explored using ABS to print a building of plastic.

“We were working back and forth on how this would work,” says Rebecca Gillogly, who received a master’s degree from UT Knoxville in May. “Nobody knew how to do it. We were figuring it out together, which was great. There was the realization that nobody ever has all the answers.”

While architects can turn to manuals and decades of research on brick and steel and glass, Lucas Tryggestad, associate director and studio head with SOM, says, “There’s no ABS or 3-D printed manual on how to build.”

“There was no precedent for the material or for the form,” says Leif Eikevik, SOM architect. “It was from the ground up on every level. There’s always a precedent in the architectural world. We felt this was carte blanche.”

They began with the idea for zero waste in energy or materials. Usual building sites generate piles of castoff 2 X 4 wood pieces, crumbled bricks and shattered glass. Instead, this project would produce–by printing— a building with exactly what was needed and no more.

Yet, how?

The SOM team also heard questions issued as challenges from ORNL: Why would you 3-D print a building? What can you do with 3-D printing that’s different from traditional manufacturing?

“We’ve been building buildings the same way for centuries,” Jackson says. “What would it look like if we removed the constraints of buildings? What would it look like to build with what you want to be the design instead of what it has to be?”

AMIE 1.0 by the numbers:

13,500: Pounds of plastic, which can be ground up and reused in the future

210: Interior square footage of the 38-foot long, 12-foot wide and 13-foot tall structure

20: Hours to print the PUV

2: Passengers the PUV can carry

35: Miles of distance the PUV can travel on electric charge only

60: MPH, rate of the PUV’s top speed

4: Weeks to print the structure, made of 80 percent ABS composite

3: Weeks to assemble the structure

20: Partners involved in the project

3.2: Kilowatts in the solar array

20: Number of C modules printed to create 10 0 modules

2: Number of AMIE’s overhangs

9: Months from research to design to printing to assembly

In their studio class, UT architecture students grappled with those questions as well and turned to nature and art for their answers. They studied and developed their designs based on seashells, dragonfly wings, origami and bones. Each lightweight, delicate. Each strong.

For, while the students grappled with their creations, SOM designers understood the issues from going there first while they designed AMIE. Tryggestad and other SOM team members traveled from Chicago to meet with the students and videoconferenced in for classes and meetings as they focused on creating with this new element.

“We were learning together,” Tryggestad says. “They were seeing firsthand a true collaboration. It was not just an SOM or Oak Ridge or UT project.”

Through the research and the challenges, the finished AMIE design morphed from the initial receipt drawing. SOM architects developed a plan created around oversized, printed Cs that joined together to create Os, which formed the caterpillar-like framework tube of the printed building–complete with structural support and insulation. In preparing to print the 38-foot long, 12-foot wide structure, the architects found that some steps could be removed from the usual building process. Ordinarily, when architects send a 2-D drawing of a project to contractors, that begins a sometimes months-long back and forth on plans and changes to them and the design.

“With AMIE, the actual model itself is translated to the building,” says Tryggestad. “It takes out so many layers for potential miscommunication. And it was so rapid. It would take things that usually take weeks or months (down) to a few hours.”

AMIE 1.0 is the College of Architecture and Design’s third foray into seeking energy solutions with its designs.

UT Zero: A 300-square-foot project in 2006 that focused on photovoltaic power, shading devices, efficient translucent enclosure and floor-mounted LED lights toward net zero on energy.

UT Zero: A 300-square-foot project in 2006 that focused on photovoltaic power, shading devices, efficient translucent enclosure and floor-mounted LED lights toward net zero on energy.

Living Light Solar House: As part of the U.S. Department of Energy’s 2011 Solar Decathlon, this structure used a transparent double façade, passive heating, integrated lighting and an electric car-charging station.

Living Light Solar House: As part of the U.S. Department of Energy’s 2011 Solar Decathlon, this structure used a transparent double façade, passive heating, integrated lighting and an electric car-charging station.

From printing a scale model to printing the actual structure, the project required only sending it to a larger-scale, 3-D printer housed at the ORNL Manufacturing Demonstration Facility (MDF).

As printing began, another partner’s strengths came into play. Gavin Mabe, who had sat at Pete’s with the others, posing questions and signing his name on the receipt, works as a product engineering manager for Clayton Homes, one of the nation’s largest builders of manufactured housing.

“We were curious,” Mabe says of why the nation’s largest builder of manufactured housing joined the project. Also, he acknowledges, it would open doors for them to work with new companies and with ORNL.

After the pieces were printed at the MDF, they were trucked to another site for painting and smoothing of the edges. The pieces then were transported to Clayton’s facility in the Knoxville suburb of Halls. There, a Clayton team assembled the Cs into Os and finished out the project, which included a micro-kitchen with a trundle bed.

And, in tackling one assembly challenge, team members experienced the agility of 3-D printing. The door frames on each end had extruded metal frames. To carve out a half-inch on each doorway to make the frames fit would mean days and days of work and many ruined drill bits to cut through the carbon fiber-reinforced plastic. Instead, in four hours the team had 3-D printed frames that fit.

“It really showed how additive manufacturing could be useful in construction,” Mabe says.

Collaboration allowed the team to work through other problems and quickly find solutions to keep the project racing toward completion. In the beginning, the printer took 14 hours to create a C section. However, team members optimized the design and managed to cut the print time in half.

“Between the builders and the architects, there are usually compromises that have to be made,” says Tryggestad. “We didn’t have any to be made.”

“We have a huge explosion of building science and technology now, when everything is possible.”

And the project wrapped on time for unveiling to worldwide acclaim during the U.S. DOE’s Office of Energy Efficiency and Renewable Energy Industry Day. Nine months after work began and 11 months after the “what ifs” around the table.

But the questions haven’t stopped.

The Governor’s Chair team has begun to consider how an AMIE 2.0 might look. Could they 3-D print micro-apartments? Could they 3-D print transit stop shelters? And through its continued use, other questions could be answered, such has how will rain and sun affect the carbon reinforced plastic?

“We have a huge explosion of building science and technology now, when everything is possible,” Rose says. “What are the directions we should pursue?”

And how can the use of 3-D printed plastic be improved? How does that material improve energy usage and sharing? What other materials, perhaps plant-based, could be printed?

Scott Poole, dean of the UT College of Architecture and Design, sees AMIE as a first-step solution as the world continues to struggle with how to manage the energy produced by renewables.

“This (energy) goes back and forth,” he says. “It doesn’t go into the grid.”

Seeking answers often leads to more questions and more possibilities but not a final solution.

Jackson quotes a team member when he says, “Instead of a silver bullet, it’s more like a collection of fireworks.”

And those fireworks can serve as an exclamation point celebrating what could be possible.

“The moon-shot type of projects really engage the imagination and take you further than you thought you could go,” Jackson says.

For students with careers ahead, Gillogly says AMIE 1.0 is important for the future, for examining the possibilities and knowing that houses could be printed since, she says, the current way of building houses is unsustainable.

“Is 3-D printing the answer? I don’t know,” she says. “But I think it’s important to be asking these questions and trying to figure it out.”